Overview

Fort Novosel is the U.S. Army Aviation Center of Excellence and is home to 25,000 soldiers, family members, and civilian employees. With the mission of developing, coordinating, and deploying aviation operations, training, and doctrine, Fort Novosel conducts 24/7 airfield operations at five separate airfields and aviation maintenance complexes with approximately 600 helicopters that are based there. Their most critical mission is to operate and maintain the helicopters 24/7 so that they are available for training pilots and military services.

Fort Novosel is challenged by aging and outdated facilities and infrastructure that are in need of renovation to maintain the level of mission readiness required. Many lighting fixtures are over 25 years old and challenging to maintain. The maintenance issues have escalated due to lamp failures, ballast and tombstone failures, and the need for lens replacements.

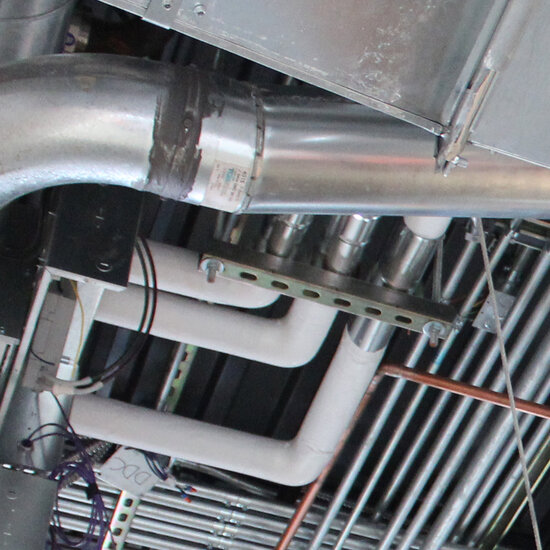

Helicopter hangars used for maintenance and training are heated during the winter months with electric infrared (IR) heaters. The existing IR units are mounted directly over the hangar bays where helicopters and other equipment are kept. Maintaining these units has been difficult and expensive, requiring close coordination with helicopter maintenance teams for access so that mission is not impacted.

Our Approach

Fort Novosel and their utility partner, South Alabama Electric Cooperative, selected Southland to review the design intent of Fort Novosel's buildings and to investigate ways to optimize their design and operational efficiencies.

A preliminary assessment was completed, which outlined a comprehensive set of energy upgrades for this utility energy services contract (UESC) program. Southland then conducted a detailed feasibility study and collaborative workshops with all Fort Novosel and Army Corps of Engineers stakeholders to develop and prioritize the energy conservation measures (ECMs) for the UESC. Out of the numerous identified ECMs, two critical ECMs were selected for implementation as an initial Phase One project:

- Upgrade to light-emitting diode (LED) lighting in the main cantonment area and airfield hangers.

- Replace inefficient and inoperable electric IR heating systems in hangers with high-performance natural gas IR heating systems.

The most immediate need is to improve lighting levels in the facilities and heating for winter operations. Other energy infrastructure needs identified will be addressed in a separate UESC phase.

Result

Phase One includes the retrofit of fluorescent lighting to LED at 50 buildings in the main cantonment area and the upgrade of high bay lighting in 6 aircraft hangers at the airfields. Additionally, inefficient and inoperable electric IR heating systems at nine hangers will be replaced with high-performance, premium-efficiency natural gas systems.

The new IR heating is designed to facilitate easier routine maintenance so that helicopters do not need to be moved to access the heaters. Significantly reducing the maintenance burden allows limited maintenance resources to focus elsewhere and provides material replacement cost savings.

Southland provided all development, design, financing, and construction and will provide ongoing performance assurance for the $9.9 million UESC project. Phase One of this project is expected to provide annual utility cost savings of $381,942 and annual operations and maintenance savings of $156,549.

Successful Partnerships

Owner: U.S. Army

Utility: South Alabama Electric Cooperative

GC: Southland Industries